Mini Split vs Central Air: Which Is Better for Your Home?

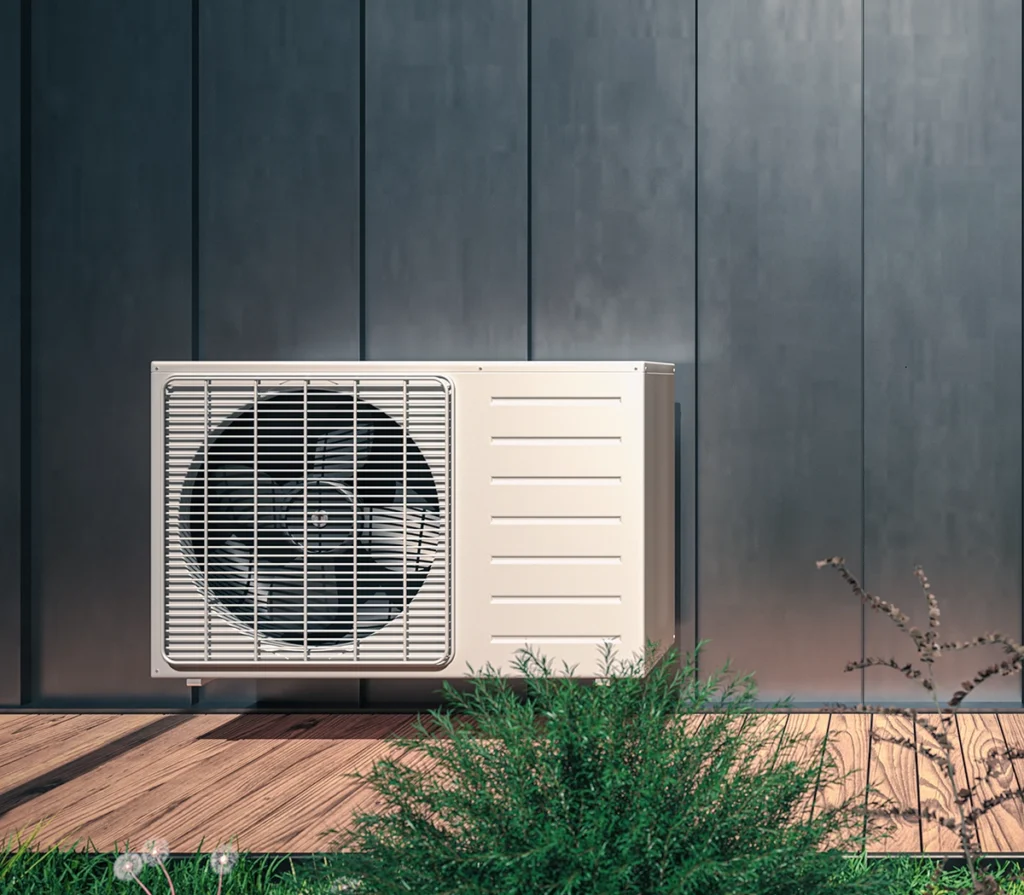

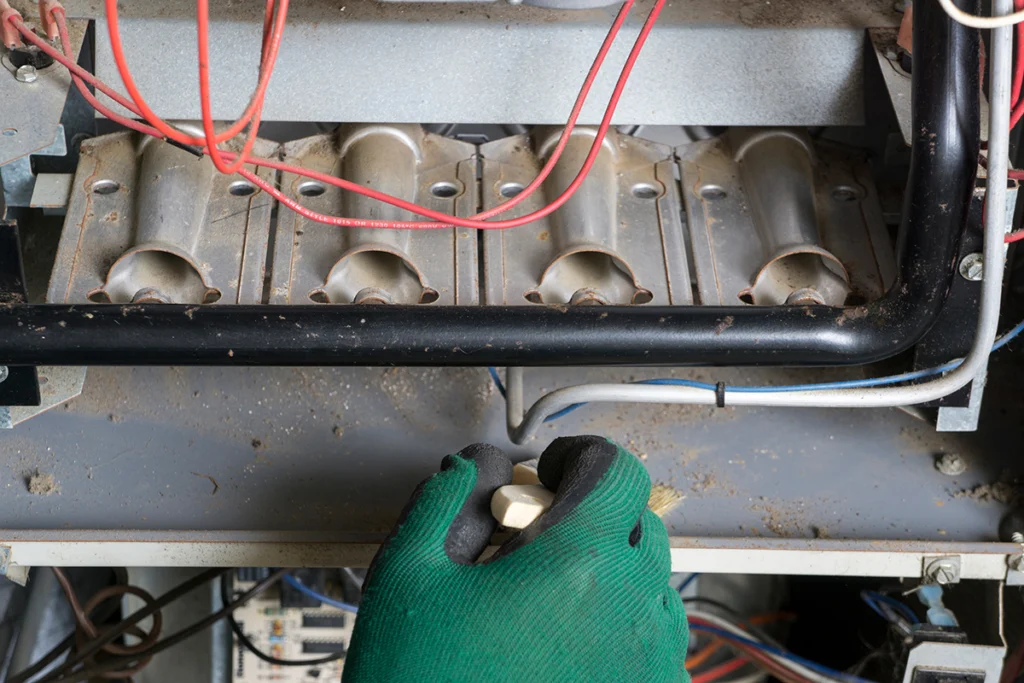

Choosing between mini split vs central air systems can feel overwhelming at first. We talk with homeowners regularly who want comfort, efficiency, and long-term value, but aren’t sure which system delivers that best. While both options cool and heat effectively, they work very differently. Because of that, the right choice depends on your home, comfort goals, and budget. At C&R Services, we help people make these decisions every day. So instead of pushing one system over the other, we break things down clearly and honestly. Let’s walk through how mini split vs central air systems compare and when each one makes sense. What Is the Difference Between a Mini Split vs a Central Air System? The biggest difference between mini splits vs central air systems comes down to distribution. Central air relies on ductwork to move conditioned air throughout the home. In contrast, mini splits use individual indoor units connected to an outdoor system. Because of that, mini splits provide zoned comfort, while central air delivers whole-home airflow. How Mini Split and Central Systems Work Understanding how each system moves air through a home makes the differences between them much clearer. While both are designed to heat and cool effectively, the way they distribute air and control temperature varies significantly. That difference plays a major role in comfort, efficiency, and system design. How Mini Splits Deliver Zoned Comfort Mini splits use an outdoor compressor and one or more indoor air handlers. Each indoor unit controls a specific space. As a result, you can heat or cool rooms independently. If you’re curious about the mechanics behind this setup, we’ve explained how mini splits work in a separate guide. That background can help you understand why zoning is such a major advantage. How Central Air Systems Distribute Air Central air systems use a single indoor unit and ductwork. Air flows through supply and return ducts to maintain consistent temperatures. This approach is part of what’s known as forced air heating and cooling. While effective, ductwork condition plays a major role in performance. Mini Split vs Central Air: Installation Differences Installation is one of the biggest factors that separates mini split vs central air systems. Mini splits typically require less invasive installation. There’s no ductwork needed, which is ideal for older homes or additions. However, wall-mounted units are visible, which some homeowners dislike. Central air installations depend heavily on existing ducts. If ductwork is already in good shape, installation can be straightforward. Otherwise, repairing, replacing, or installing ductwork can increase costs. According to ENERGY STAR, leaky ducts can reduce heating and cooling system efficiency by as much as 20 percent, which is why duct condition and installation quality matter so much with central air systems. Energy Efficiency Compared Efficiency is a major reason homeowners compare mini splits vs central air systems. Mini splits often achieve higher efficiency ratings because they avoid duct losses. They also allow room-by-room control, which prevents over-conditioning unused spaces. Central air systems can still be efficient, especially newer models. However, efficiency depends on duct sealing, insulation, and system sizing. The U.S. Department of Energy explains that fully ducted heat pump systems typically achieve efficiency ratings between 15.2 and 25 SEER2 (generally classified as central air in residential homes), while ductless mini split systems can reach ratings as high as 35 SEER2. Mini Split vs Central Air: Comfort and Control Comfort preferences often tip the scale in the mini split vs central air debate. Mini splits excel at personalized comfort. Each zone has its own temperature setting. That flexibility works well for households with different comfort preferences. Central air delivers even airflow across the home. While zoning is possible, it requires additional equipment. If comfort control matters most, mini splits usually win. If uniform temperatures matter more, central air may be the better option. Maintenance and Repair Considerations Maintenance should never be overlooked when comparing mini split vs central air options. Mini splits require regular filter cleaning and professional service, and skipping mini split maintenance can reduce efficiency over time. Central air systems require filter changes, duct inspections, and routine servicing. Understanding the key components of an HVAC system helps explain why maintenance plays such a big role in long-term reliability. Mini Split vs Central Air: Cost Considerations Cost comparisons between mini splits and central air systems depend on home size and layout. Mini splits often cost less upfront for smaller spaces or single rooms. However, multi-zone systems can become expensive as additional indoor units and longer line sets are added. Size matters here too, since proper mini split sizing can impact long-term costs, comfort, and efficiency. Central air systems may cost more initially, especially when duct upgrades or new duct installation are required. Still, for larger homes, a single properly sized system can provide consistent comfort across many rooms more cost-effectively than installing multiple ductless units. When Each System Makes More Sense Mini splits are often best for: Homes without ductwork Additions or renovations Zoned comfort needs Central air is often better for: Larger homes Existing duct systems Whole-home airflow preferences While mini splits are a great fit in many situations, they aren’t ideal for every home. Reviewing the potential drawbacks of mini split systems can help set realistic expectations before making a decision. Our Professional Take at C&R Services At C&R Services, we don’t believe in one-size-fits-all solutions. We evaluate your home, comfort goals, and long-term costs before recommending a system. Our job is to help you choose the system that actually makes sense for your home. If you’d like to explore your options further, our mini split services page explains installation options, zoning possibilities, and what to expect from a ductless system. On the other hand, if a traditional setup makes more sense, our AC installation services page outlines system options, replacement considerations, and what to expect during installation. If you’re located in Tyler or East Texas, we’re always happy to walk you through the pros and cons in more detail. You can contact our team